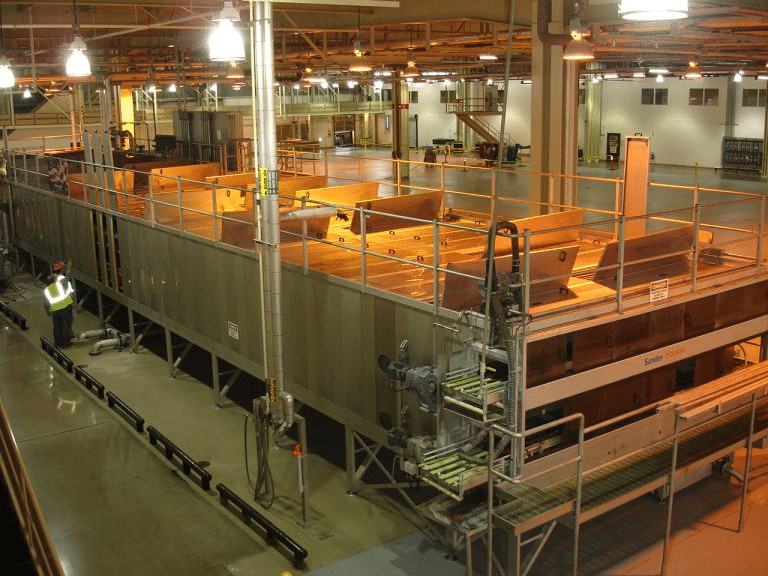

Smart Machine Technologies custom-builds food and beverage tunnel pasteurizers for improved flavor, safety, and easy integration into your manufacturing process. A tunnel pasteurizer consists of large chambers or cabinets constructed out of food-grade stainless steel and other high-quality parts.

Smart Machine Technologies custom-builds food and beverage tunnel pasteurizers for improved flavor, safety, and easy integration into your manufacturing process. A tunnel pasteurizer consists of large chambers or cabinets constructed out of food-grade stainless steel and other high-quality parts.

Businesses that package consumable products in glass jars, bottles, or cans use tunnel pasteurization to increase product safety and prolong shelf life.

We can manufacture our equipment in any size or dimension with technical specifications that fit the exact needs of your production line and products. Our machines are durable, reliable, and adhere to the highest hygiene standards.

Benefits Of Tunnel Pasteurization:

- Kills microorganisms & pathogenic bacteria such as Salmonella, E. Coli, and Listeria.

- Halts the growth of yeast & reduces the spread of diseases

- Efficient & effective process of keeping products safe for consumption

- Preserves freshness & enhances shelf life

Request A Tunnel Pasteurizer Quote Today

COMMERCIAL-GRADE EQUIPMENT

Tunnel pasteurizers are a large part of the manufacturing process for food and beverage items. Products enter the pasteurizing chamber on a conveyor belt system and are heated with water or steam to kill pathogenic bacteria and inhibit enzymes. The products then enter a cooling chamber before exiting the machine. They are typically sprayed with cold water that returns them to the desired temperature.

At SMT, we’re a tunnel pasteurizer manufacturer that provides commercial-grade equipment for improved hygiene levels and competitive production rates.

Request A Tunnel Pasteurizer Quote Today

CUSTOMIZED AND EASY TO OPERATE

A tunnel pasteurizer is a great solution to providing a simple yet reliable alternative to flash pasteurization units. They are available in various sizes, dimensions, and technical specifications. With so many options, there’s sure to be tunnel pasteurization equipment that can fit your exact needs.

Dimensions and technical design depend entirely on the product, container, and required output. Food products can be heated either directly or indirectly by internal or external heat exchangers.

It’s critical that the equipment remains hygienic, safe, easy to maintain, and has a legitimate warranty. Energy transmissions typically occur through continuous water spray, steam, or hot water baths.

Flavor deterioration is one of the biggest problems with pasteurization. This is why in the food and beverage industries, it’s essential to use equipment specifically designed for the product you’re treating.

Tunnel Pasteurizers Made in the U.S.A.

At Smart Machine Technologies, we craft high-quality tunnel pasteurizers right here in the United States, utilizing materials sourced domestically. Our tunnel pasteurizers are custom-built to meet the specific requirements of your application, ensuring precision, reliability, and efficiency. As a U.S.-based fabricator, we are eligible to bid on and fulfill government contracts, making us a trusted choice for projects that require adherence to regulatory standards and top-notch craftsmanship. You can rely on Smart Machine Technologies to deliver solutions that reflect the excellence of American engineering and innovation.

Request A Tunnel Pasteurizer Quote Today

Foods & Liquids Commonly Processed With Pasteurization

Some of the most common food, liquid, and particulates items that undergo the tunnel pasteurization process include:

Liquids

- Milk

- Juice

- Wine

- Beer

- Carbonated Beverages

- Cream

- Water

- Salad dressing

Read More: Why Use A Pasteurizer For Beer?

Particulates

- Soup

- Stew

- Yogurt

- Baby food

- Sauce

- Canned goods

- Egg

Frequently Asked Questions

How much floor space will my industrial pasteurizer take?

When considering how much floor space an industrial pasteurizer will require, it’s important to keep in mind how long it takes to complete a cycle.

A cycle typically takes 45 minutes to an hour to complete, and the machine often features a long conveyor belt. Plus, the pasteurizer will typically be divided into six 15-minute zones to ensure proper processing.

To determine the appropriate size for your needs, you’ll want to consider how many products you need to process per minute, such as cans or bottles. For example, if you need to process 50 products per minute, you’ll need a machine that is 50×15, which will help you determine the necessary size for your operation.

What is the current lead time for pasteurizer equipment?

The lead time for pasteurizer equipment can vary depending on the specific circumstances. Typically, it takes about two weeks to get the drawings submitted to a new client. Once the drawings are approved, it takes approximately 16 to 18 weeks to build the equipment.

When the equipment is ready, SMT employees will come to help with the installation and startup process to ensure that it’s working correctly and efficiently. They are available to travel anywhere in the US.

What maintenance do industrial pasteurizers require?

The most important thing is to keep pasteurizers clean to ensure proper functioning. They require very little maintenance, and if they are kept clean, they can be considered relatively maintenance-free.

It’s also crucial to keep the water in your equipment clean to avoid any problems with pasteurizers that could cause line stoppages and equipment failures.

What are pasteurizers’ utility requirements?

Pasteurizers’ utility requirements include water, electricity, and possibly steam, depending on the type of pasteurizer you use:

- During startup, pasteurizers require a significant amount of water, but once they’re up and running, they operate with minimal water usage.

- The machines are equipped with six pumps, which means they use a relatively large amount of electricity.

- We calculate the heating and cooling needs of each customer based on the product being pasteurized. The specific needs vary from customer to customer and are taken into consideration to ensure that the equipment is tailored to their unique requirements.

If you don’t have a boiler or chiller, we can provide these components as part of our offering for added convenience. While we do not manufacture them ourselves, we are happy to provide them as an all-in-one solution for our customers.

IMPROVE THE FLAVOR AND SAFETY OF YOUR FOOD AND BEVERAGE PRODUCTS

A tunnel pasteurization system from SMT will seamlessly fit into your manufacturing process. Technical design and dimensions depend entirely on your product, container, and required output. We can custom-design our systems with technical dimensions that meet your company’s specific needs. Contact us below to get pricing or a quote.

Contract

Contract Food & Bev

Food & Bev