Full-service fabricator SMT’s 10BBL indirect fire & electric solution will let Elst Beer brew its liquid gold.

Full-service fabricator SMT’s 10BBL indirect fire & electric solution will let Elst Beer brew its liquid gold.

Southbound and Hopping

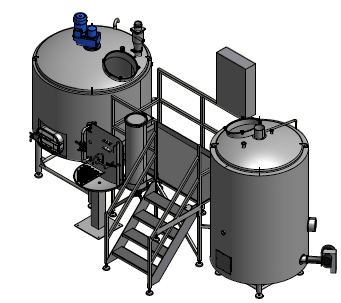

Principals of Knoxville’s (Tenn.) newly established Elst Brewing Co. — founded in 2017 to “create fine beers that speak to people with an obsession for beer” ― believe the brewhouse is the heart of a brewery. So when they considered which company to enlist to get the exciting enterprise off the ground they quite fittingly selected the equivalent of the heart surgeons of the brewery world ― Ridgeway, Va.-based Smart Machine Technologies’ (SMT) Brewery Solutions.

Here’s Why Elst Picked SMT for Their Brewing Equipment:

We chose SMT because of their ability to work with us on custom specs for the brewhouse and they are located close by. The brewhouse is being manufactured to fit the best layout for our space. Our mash tun will give us the flexibility to mash at different temperatures throughout the mashing process. This is a technique that is used in traditional Belgian brewing and we feel that it is an important feature for the brewhouse.

Source: Elst Blog Post

Tanks for the Memories

SMT, which builds 3.5BBL to 100BBL brewhouses that use steam power (gas or electric) or enclosed indirect fire, helps clients every step of the way, from the initial designs to the final installation. Its wide array of stainless-steel tanks are constructed of the highest grade materials available on the market today, and its premium steel tanks are also easier to clean and maintain, which means saving hours of backbreaking labor down the road.

SMT prides itself on helping customers achieve and maintain a competitive advantage and to that end offers emergency repair services and possesses an in-depth understanding of the functionality, efficiency, economic and safety challenges faced by today’s brewers. Those virtues and capabilities have helped SMT win over many a brewer, just as it did in the case of Elst Brewing.

Beginnings of Brewhouse Powerhouse

Set to open during 2018, this past summer Elst Brewing stakeholders carefully selected and purchased a building in the 2400 block of North Central Street that will become the site of Elst Brewery located in historic Old North Knoxville (ONK). Some aspects of the existing structure were salvaged during the mostly demolition process, which was followed by approval of the architectural drawings and the commencement of construction. It was during the phase that SMT was brought in to begin the fabrication process for the brewing equipment.

Brewery Design Free of Hiccups

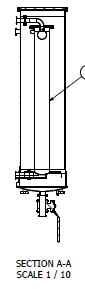

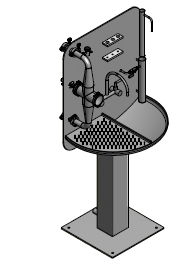

The brewhouse also includes a redesigned hopback mounted on the front of the platform. The hopback is filled with hops and gives the brewer an opportunity to run several passes from the kettle/whirlpool to the fermenter. The brewer’s sink sits in front of the platform and will give Elst brewer Chris Sexton access to gravity and clarity information.

Mind Over Grind

Future Foamy Fortunes

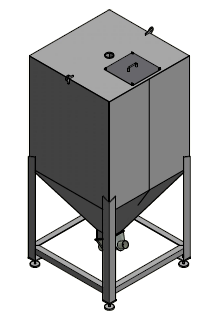

The two 10BBL unitank fermentation tanks and the 20BBL fermentation and brite tanks will be the first of many additional such units added over time as Elst Beer builds up its brand and meets its Knoxville, and eventually regional, market goals. With already well in excess of a dozen varieties set to quench discriminating thirsts upon its imminent opening, the Elst Brewery will in short order delight beer lovers in the adjacent Elstwhere tasting room.

About Elst Beer

Founded in 2017, Elst Beer literally means a sanctuary for beer. To that end, with its first brewery and tasting room set to open during 2018, the business’ stated objective is “to create fine beers that speak to people with an obsession for beer.” Based in Knoxville, Tenn., company owners say the Elst Brewery is “a place for us to focus and create great beers for your enjoyment! Our favorite part of creating beer is sharing it with others.”

About Smart Machine Technologies Inc.

SMT manufactures large tanks and vessels for a wide range of industries. SMT’s designs and fabrications help companies improve their throughput and competitiveness. Founded in 1975, Smart Machine operates its approximately 100,000-square-foot shop out of Ridgeway, Va.

For more information, call 877-703-3280 or visit smartmachine.com.

Contact Us to Learn More About Building Breweries

Contract

Contract Food & Bev

Food & Bev