Industrial steam box and tunnel pasteurizers are two popular methods to improve the taste, safety, freshness, and shelf life of food and beverage products. The choice between the two methods will depend upon your products, needs, goals, and manufacturing processes.

Read on to learn more about these two types of pasteurizing machines and which one is the ideal solution for your products.

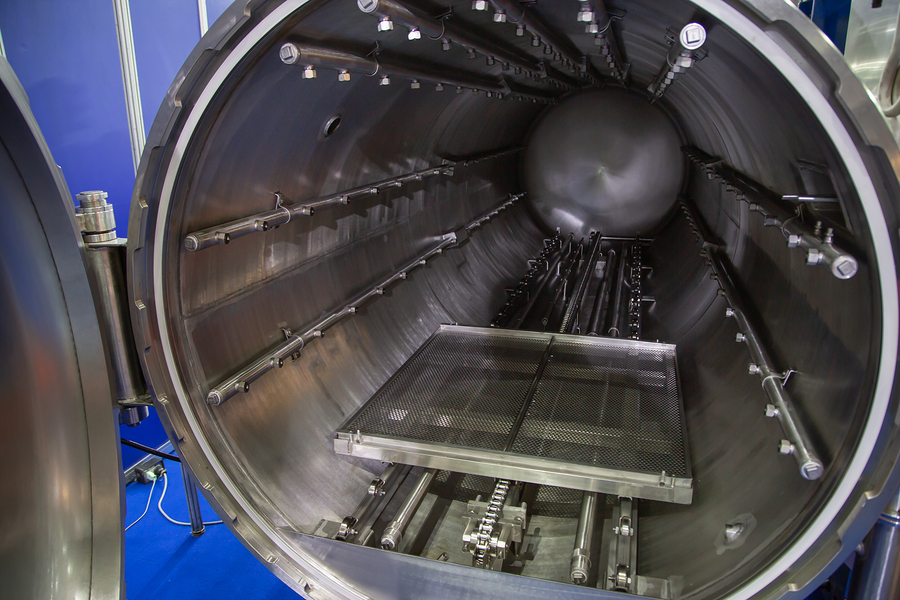

STEAM BOX PASTEURIZING

Companies that need to pasteurize large quantities of food or beverage products can benefit from a steam box pasteurizer. The process starts with an enclosed area that uses steam to slowly heat products to a certain temperature for a specific time. The food and beverage products are then allowed to cool back to room temperature.

BENEFITS OF STEAM BOXES

There are many distinct advantages to using an industrial steam box pasteurizer from Smart Machine Technologies:

- Reliability—We only use high-quality parts and components to build our steam boxes. The result is a well-engineered machine that will stand up to the daily rigors of manufacturing and the test of time.

- Custom volume—You can pasteurize large batches of product at a time to meet your production volumes.

- Versatile—No matter what kind or type of product you need to pasteurize, you can do so independently of your production lines.

- Size—If floor space is at a premium, steam box pasteurizers are smaller than alternatives.

COST OF A STEAM BOX

One of the main differences between a steam box and a tunnel pasteurizer machine is that the former does not have the conveyor features normally associated with the latter. As such, steam boxes are a less expensive option.

The most significant price influencer of a steam box is its size. We can manufacture them to be small enough to fit a few hand-stacked crates or large enough to fit an entire pallet.

TUNNEL PASTEURIZERS

Depending on your products and manufacturing processes, a tunnel pasteurizer can come in various configurations. Generally speaking, tunnel pasteurizers consist of several chambers that are heated directly or indirectly through hot water baths, steam, or continuous water sprays.

Companies that package consumable products in cans, bottles, or glass jars use tunnel pasteurizers. However, they’re not best for beer kegs due to their size and the fact that the entire process takes far too long to heat and cool.

Commercial tunnel pasteurizers are ideal for recurrent manufacturing processes. No matter the product volume that passes through your production line, we can scale our machines to meet your exact requirements.

BENEFITS OF TUNNEL PASTEURIZERS

A tunnel pasteurizer from Smart Machine Technologies offers the following advantages:

- Ideal for commercial craft brewers who can or bottle their products

- Highly effective at inhibiting microorganisms and pathogens

- Great for halting yeast growth and curtailing secondary fermentation

- A tunnel pasteurizer is highly efficient and can rapidly process large volumes of products

- Requires fewer people to operate – conveyors move products through the pasteurization process

- Works seamlessly as part of an automated production line

- Built with high-quality components and parts for high performance and durability

COST OF A TUNNEL PASTEURIZER

Tunnel pasteurizers use a conveyor belt to move product from chamber to chamber. The conveyor belt and size of the tunnel pasteurizer directly influence the overall cost.

Maintenance can also be fairly expensive, and tunnel pasteurizers require significant floor space. However, the benefits outweigh the expenses as you’ll never have to worry about over-pasteurization due to the ability to control temperatures in each zone.

TYPES OF PRODUCTS YOU CAN PASTEURIZE

Here are a few of the many different types of products that you can pasteurize with a tunnel or steam box pasteurizer:

- Milk

- Canned goods

- Beer

- Wine

- Baby food

- Sauces

- Soup

- Cream

- Salad dressing

- Stew

- Juice

- Yogurt

- Eggs

- Water

PROTECT YOUR PRODUCTS, CONSUMERS, AND REPUTATION

Pasteurization equipment from Smart Machine Technologies helps preserve freshness while increasing your products’ safety and shelf life. Our expert engineers will sit down with you to custom-design a steam box or tunnel pasteurizer that fits seamlessly into your production line. Contact us below for more information.

Contract

Contract Food & Bev

Food & Bev