In the event of an explosion, how will you protect your personnel, equipment, and stock? Combustible dust explosions occur regularly in a wide range of industries, sometimes with devastating consequences. Be sure you have strong, effective safeguards in place to protect your people from injury and your company from damage.

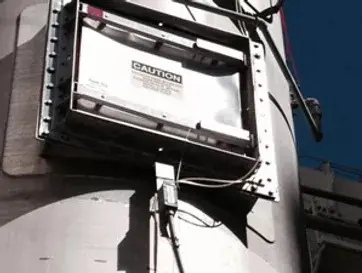

SMT’s robust explosion relief doors and explosion vent panels are engineered to provide superior, cost-effective pressure relief protection in the event of an explosion.

Which Industries Use Explosion Relief Doors and Hatches?

Combustible dust explosions are most commonly associated with the agriculture and mining sectors, but catastrophic overpressure events can occur in a wide range of commercial and industrial contexts. Here are just some of the environments where explosion relief doors and hatches can provide critical personnel and asset protection:

Food Processing: Food plants often handle combustible organic dust like sugar or flour. Explosion relief doors can be crucial in containing and safely venting any accidental combustion, safeguarding employees, and reducing downtime.

Woodworking & Lumber Mills: Sawdust and wood flour can become highly combustible while woodworking equipment can easily provide an ignition source. Explosion relief doors offer a controlled outlet for any explosion.

Pharmaceuticals: Solids processing in pharma can create combustible dust. Explosion relief doors are invaluable for maintaining a safe environment, especially given the sensitive nature of pharmaceutical manufacturing.

Chemical Manufacturing: Any fine chemical is prone to combustible dust events, and many common compounds can be explosive or flammable in their own right. Explosion relief doors provide a targeted release point for any overpressure.

Metalworking: Grinding and cutting processes can produce combustible metal dust. Explosion relief doors are essential to quickly vent pressure and limit the scope of any incident, helping to avoid injury, damage, and shutdowns.

Textiles: Cotton and synthetic fibers can become airborne and create a combustible environment in mills or clothing factories. Explosion relief doors help to safely release this pressure, minimizing the risk of larger, uncontrolled incidents.

Coal Mining & Handling: Coal dust is highly combustible. Properly installed explosion relief doors are essential in processing or storage areas to reduce the impact of potentially devastating combustion events.

Plastics & Rubber Manufacturing: These industries produce fine poly-carbon particulates that can become combustible in some situations. Explosion relief doors are essential to safely vent overpressure events in any bulk-handling facilities.

Recycling Facilities: Plastic and glass recycling activities can produce several different combustible dusts in the same environment. Explosion relief doors can be calibrated to handle blast events in these mixed environments.

Agriculture: Grain silos and other bulk storage facilities present a high risk for combustible dust explosion. Installing properly calibrated explosion relief doors is essential to protecting staff, property, and valuable crops.

How Does an Explosion Door Work?

Explosion relief doors are designed to open once a predetermined pressure is reached in the vessel or space they are protecting. In the event of an explosion, the door is instantly triggered, safely absorbing and venting most of the energy of the explosion.

Doors can also designed to prevent air from entering the space where the explosion occurred, helping to suppress the chance of fire by limiting the oxygen needed for further combustion.

Explosion relief doors are more expensive to install than off-the-shelf blast vent membranes, but last far longer. On average, explosion relief doors last 10-15 years, but a door’s effective life span can vary significantly depending on the application where it is used.

Most importantly, unlike vents, explosion relief doors do not need to be replaced after any overpressure event.

Doors can also be calibrated to respond to lower pressure events than prefabricated vents and can be adjusted if your pressure protection requirements change.

How Does an Explosion Vent Work?

An explosion vent is a pre-scored metal membrane engineered to rupture when pressure hits a specific point, offering a controlled release path for combustion hazards during an explosion. By rapidly reducing pressure during a dust explosion, vents help to minimize damage to your containment vessel and the surrounding areas.

Explosion vents offer cost-effective protection against overpressure events, especially in ductwork or other non-contained spaces where explosion doors cannot be used.

However, unlike explosion doors, vents need to be replaced once burst. Also, unlike doors, vents cannot be recalibrated in place and will need to be replaced if your process or pressure requirements change.

Vent membranes also tend to suffer fatigue over time and need to be replaced periodically to ensure adequate protection.

Which Explosion Door Do I Need?

For explosion protection, the number and size of doors required is dependent on many factors. These may include:

- How susceptible your materials and process are to combustible dust events

- The volume of air or gas in the vessel or piping being protected

- The structural integrity of the containment or process vessel

- The typical dust concentration occurring in the protected area

Features of Our Explosion Relief Doors

SMT explosion relief doors are engineered to afford superior pressure relief protection for your personnel, capital equipment, and infrastructure.

Our doors feature a robust magnet and pre-loaded spring relief combination that ensures outstanding performance, reliability, and repeatability — so you know your doors will open when needed, every time.

When closed, our floating, spring-loaded door panels compress flexible gaskets to a rigid frame, ensuring a proper positive seal. SMT explosion relief doors also feature:

- Stainless steel latch springs, hinges, and fasteners

- Stainless steel, carbon steel, and aluminum door frame with stainless steel or aluminum door panels

- 3 or 4½ inch standard frame sizes

- Self-lubricating sleeve bearings

- Heat- and cold-resistant designs available for temperatures from -65 to +1,000 F

- Lightweight door panel materials weighing less than 2.5 lb/sq.ft

- Fully assembled with frame bolts in place for easy installation

- Food-grade designs available built with FDA, USDA, and NSF-approved materials

- A unique dual-purpose design that provides both effective pressure relief protection and emergency access or egress for personnel in the event of a blast or fire.

Explosion Relief Doors Made in the U.S.A.

At Smart Machine Technologies, we manufacture top-quality explosion relief doors right here in the United States, using materials sourced domestically. Our explosion relief doors are constructed to meet the stringent safety standards of various industries, ensuring reliability, durability, and effectiveness in protecting personnel and property from the hazards of explosions. As a U.S.-based fabricator, we are eligible to bid on and fulfill government contracts, making us a trusted partner for projects that require compliance with regulatory standards and top-notch craftsmanship in explosion protection equipment. You can trust Smart Machine Technologies to provide reliable explosion relief doors that exemplify the excellence of American engineering and innovation.

Protect What Matters With a Quality Smt Explosion Door or Hatch

Since 1975, we have been helping companies protect their people and their assets with robust, reliable explosion doors and explosion hatches. With over 5,000 doors installed, we stand behind our commitment to providing you with the quality pressure relief devices you need to stay safe.

Click below to learn more about SMT’s tough, reliable, and cost-effective explosion relief solutions.

Contract

Contract Food & Bev

Food & Bev