Our safety doors have a moving door panel hinged on a door frame This door assembly can be mounted horizontally or vertically. They come in a variety of standard and custom sizes.

Learn More About Our Safety Devices

One of Our Safety Doors in Action:

Safety Door Mounting Options

Mounting the Door Assembly

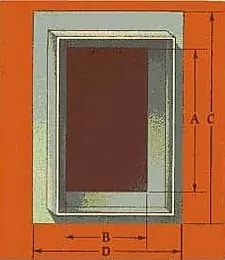

PSD explosion relief doors can be mounted in any position, with the hinge axis vertical, horizontal (top or bottom of door) or angled. The opening required in the housing is equal to the actual door size plus either 6 or 9 inches in both the length and width dimensions. See the door frame table above.

Safety Door Sizing

Standard Door Panel Sizes

| Panel Width (inches/mm) | Panel Height (inches/mm) | Opening Area (square feet) |

| 24 / 0.6096 | 24 / 0.6096 | 4.0 / 0.372 |

| 21 / 0.533 | 21 / 0.533 | 3.06 / 0.284 |

| 21 / 0.533 | 45 / 1.143 | 6.56 / 0.609 |

| 12 / 0.305 | 12 / 0.305 | 1.0 / 0.093 |

Door Frame Sizing

| Frame Width | Inside Height A | Inside Width B | Outside Height C |

Outside Width D

|

| 3 inches | A | B | A + 6 | A + 6 |

| 4.5 inches | A | B | A + 9 | A + 9 |

Sizing if you calucalated the minimum area required

Sizing if you calucalated the minimum area required

If you know the door area based on the applicable Standards, processed materials, vessel size, strenght and configuration you may be able to use a standard door size or request a custom door size.

We will calculate the door size if you don’t know the minimum area required

The number and size of complete doors required is a function of the vent ratio for the particular application (vent ratio is the ratio of pressure relief area required to the total volume enclosed in the housing or vessel). We can calculate the minimum area required from the current standards in your area.

Safety Door Features

3000 Series aluminum

- These standard stainless steels: 304, 316

- Ask for special stainless steel alloys and these options:

- 2B Mill Finish

- Material Certifications

- Identification Labels

Door Panel Temperature Ranges

- -65F to 180F (82C): Commercial grade toughened epoxy

- 181F to 250F (121C): Modified epoxy film adhesive

- 251F to 350F(177C)

- 351F to 1000F Ceramic adhesive

Frame Materials

3000 Series Aluminum

- Standard Stainless Steels: 304, 316

- Special Stainless Steel Alloys Also Available: 301/302, 310, 347

Frame Styles

- Classic “Shoe Box” style with overlapping faces

- Butt Style with a Smooth Joint

Gasket Types and Temperature Ranges

SBR Rubber, Black or White -20 F / 212F

- Buna-N Nitrile, Black -30 F / 250 F

- Silicone Rubber, White -80 F / 420 F

- Using FDA recognized (food grade) components, beveled or square profile

- Using non-FDA recognized (non- food grade) components, square profile

- Silicone Rubber, White Food Grade, 2-part interlocking gasket system -80 F / 420 F

- Viton, Black -10 F / 400 F

- Woven Silica to 1000F

Special Options

Thermal Insulation

- 5.4 .hr-ft²-ºF/Btu

- Protective Cages

- Solid bar construction

- Retraint Cables

- Aircraft Cable, 1/8th Dia, Braided Stainless Steel

- Alarm Switches for Remote Indication of Door Opening

- 4X, 7X, Haz Loc NEC 501 rated, ATEX rated

- Strip Heaters to Prevent Icing

- Factory installed, with pigtail leads.

- Field Calibration Fixture

We Do Not Use Conflict Materials

Section 13(p) of the Securities Exchange Act of 1934 and Rule 13p-1 thereunder (collectively, the “conflict mineral rules”) require Philadelphia Safety Devices (PSD) to make certain disclosures concerning supply sources for conflict minerals – principally consisting of gold, tin, tungsten, or tantalum – that may be necessary to the manufacture or functionality of our products.

Philadelphia Safety Devices neither uses nor adds any conflict materials to make their products.

Get a Quote for a PSD Safety Door

Our technical staff will contact you to assist with the selection of the correct doors for your applications.

Sizing if you calucalated the minimum area required

Sizing if you calucalated the minimum area required 3000 Series aluminum

3000 Series aluminum 3000 Series Aluminum

3000 Series Aluminum SBR Rubber, Black or White -20 F / 212F

SBR Rubber, Black or White -20 F / 212F Thermal Insulation

Thermal Insulation

Contract

Contract Food & Bev

Food & Bev