There’s a lot that can go wrong between the design phase of building a microbrewery and the first sip to hit a customer’s lips. Brewing a batch of beer requires many steps, exact portions, precise timing, and a scientific approach that borders obsession. Tweak one small thing and the process, and everything goes wrong.

There’s a lot that can go wrong between the design phase of building a microbrewery and the first sip to hit a customer’s lips. Brewing a batch of beer requires many steps, exact portions, precise timing, and a scientific approach that borders obsession. Tweak one small thing and the process, and everything goes wrong.

Start with Great Equipment & a Solid Design

If you want to be able to brew great beer, make purchasing high-quality equipment one of your top priorities. Brewing equipment is the canvas in which brewers paint their masterpieces, which is why that equipment needs to function flawlessly and consistently, batch after batch.

Equipment plays an essential role in creating a brew, from milling, mashing, lautering, boiling, whirlpooling, cooling, fermenting, maturing, filtering, to final packaging. Brewers need to be able to go through each process without encountering issues along the way.

Common Microbrewery Problems

Installation: We insist on being onsite during installation because customers often run into unforeseeable issues that are beyond their expertise. We’re centrally located in the U.S., so it’s easy for our engineers to travel onsite across the country.

- Cleanliness: Using unclean equipment isn’t an option for any level of brewing, but cleaning costs time and money. We use high-quality stainless steel because it makes cleaning easier.

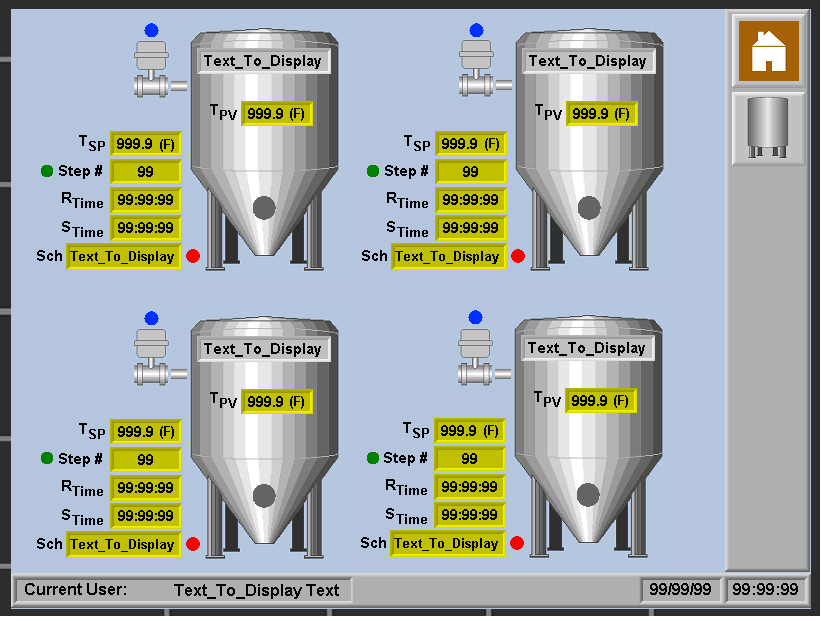

- Temperature Consistency: When brewing beer, temperature is another vital component of the process. Things must be heated to exact temperatures and those temperatures must be maintained for set timeframes. Automation can help simplify this process.

- Scalability: How quickly can your operation scale to meet customer demand? There are several factors that must be considered, from batch size and facility size to equipment procurement and financing. For starters, are you shipping equipment from overseas? Because there are advantages to purchasing American made brewing equipment.

- Replication: So, you’ve just brewed the most incredible beer ever tasted by man. The first question one must ask is, can the process be replicated? If not, you aren’t going to have much long-term success. Automation can help take replication to the next level.

- Capacity: Every single component of a brewing operation needs to be carefully planned, otherwise, you could end up with detrimental bottlenecks that cost time and money.

- Growth: Micro-Brewr Magazine asked 61 brewers to weigh on what they wish they’d known before starting a brewery. The most common response was, “I wish we’d planned for expansion right from the start. For that reason, consider setting up your microbrewery in a facility that has room for expansion.

Interested in Starting a Microbrewery?

Working with a well-established designer, builder, and installer is a good place to start and a great way to ensure your brewing team takes all of these potential issues into consideration throughout each step in the process. It takes careful foresight and diligent planning to successfully launch a new brewery, but it also takes a sizable investment. Having a clear understanding of the cost of equipment as early in the process as possible can help tremendously with your overall planning.

Once you have an idea of how much beer you want to be able to produce, consider getting an estimate for the cost of the equipment that will be required to hit those target production goals. The equipment will likely be a large portion of your start-up cost, which is why you should get an estimate for those equipment costs as early as possible. However, keep in mind that there are going to be many other things to factor into your overall brewery cost calculations, like the building, employees, brewing supplies, marketing, and much more.

Our team can provide you with a very specific estimate of how much your microbrewery is going to cost.

SMT Designs & Installs Microbreweries

We build, design and install both custom microbrewery equipment and complete turn-key breweries across the East Coast. In fact, we usually have two or three turn-key breweries set up on our production floor at any given time, so come visit us just outside of Martinsville, Virginia and see for yourself.

Use our Microbrewery Pricing Request form to get pricing for the design, build, and installation of microbrewery equipment for small nanobreweries, mid-size craft breweries, or large-scale brewing operations.

Get Pricing for a Microbrewery…..

Installation: We insist on being onsite during installation because customers often run into unforeseeable issues that are beyond their expertise. We’re centrally located in the U.S., so it’s easy for our engineers to travel onsite across the country.

Installation: We insist on being onsite during installation because customers often run into unforeseeable issues that are beyond their expertise. We’re centrally located in the U.S., so it’s easy for our engineers to travel onsite across the country.

Contract

Contract Food & Bev

Food & Bev